Innovation for Creation

We aim for customer satisfaction

Smart BusinessTechnology Research Institute

Companies that hold the best technology within the boundaries of the root industry can survive.

2Saehan technology research institute created with excellent research staff and laboratory in 2011 forms an international competition foundation and carries out various researches in order to pursue maximization of the customer satisfaction.

The excellent research staff of SAEHAN full of passion for the future technology development is carrying out systematic research from diversified perspective such as development trend of the root industry and product, improvement of product performance and process etc. in order to secure the competitiveness from the global market is devoted to developing top-notch product as a component maker.

Receding research part is promoting new technology development through bottleneck technique from an industry site and industry-academic cooperation research project such as individual research, national assignment etc.

Also have received a trade and industry minister prize in 2016 through the research project carried out in 2013 as a consistent research development activity and currently is focusing on new product and new technology research through continuous consortium with the outside institutes.

| Term | Project name |

|---|---|

| 2010 | Develop partner component vision examination system for digital electronics industry발 |

| 2013 | Develop energy reducing electromagnetic contactor and auto assembling system |

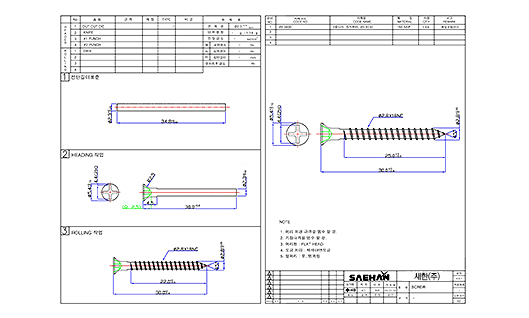

| 2013 | Develop V-shape washer screw using compression method |

| 2014 | Improve electromagnetic contactor contact for condition in order to improve cost - competitiveness |

| 2015 | Develop auto packaging transfer technology and process information management system in order to enhance projected quality |

| 2016 | Develop non-hydrodynamic damper assembled eco-friendly cup hinge with enhanced durability |

| 2017 | Develop high-intensity kitchen furniture plastic drawer and multi-cavity charge controlling technology |

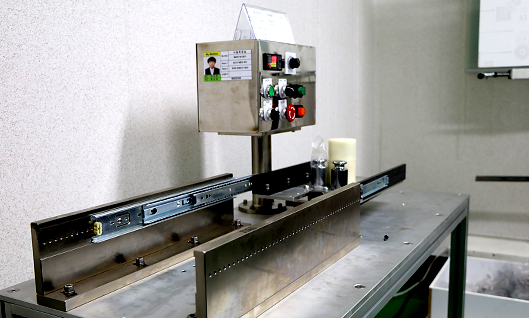

| 2018 | Improve MC 40af battery contactor process through developing upper frame terminal screw auto drive development |

| 2018 | Electromagnetic processing process improvement through developing robot-based screw auto drive system |

| 2019 | Develop waterproof eco-friendly drawer and bottom cabinetry with multi equipping part |

| 2019 | Develop plated barrel for substituting imported goods by applying projected composite material with 30% abrasion resistance increased |

| 2020 | Develop wire processing robot for fixing teeth arrangement that can process 3D structure |

| 2021 | Improve assembly process in order to enhance productivity and quality of the electromagnetic contactor UA-1 contact unit |

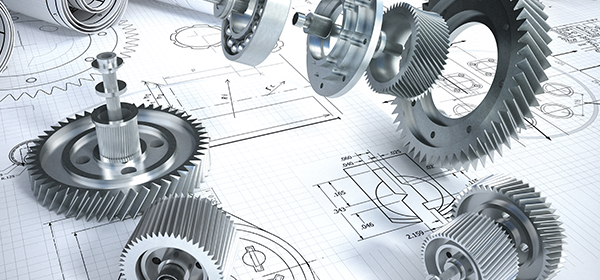

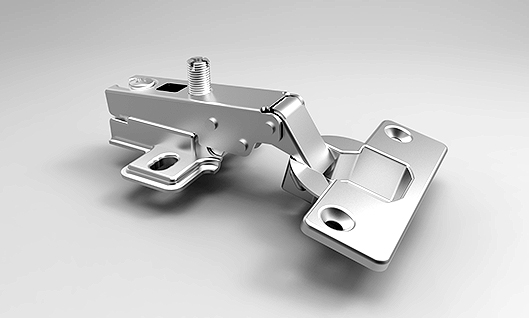

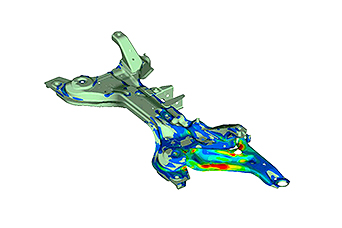

Designs furniture hardware, electronics component and module based on the accumulated designing function. The designing time is reduced by using the 3D printer enhancing the design productivity promoting cost reduction and quality enhancement through efficiency and simplification.

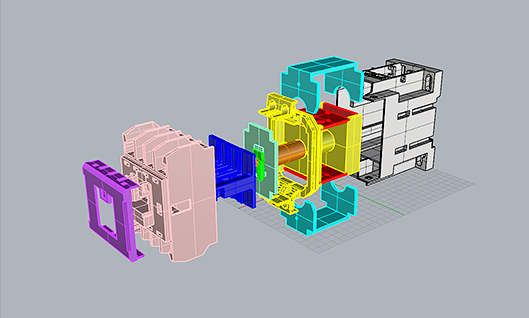

The issues during mass production is examined by establishing the DMU (digital mock up) realizing reduction of development cost and time.

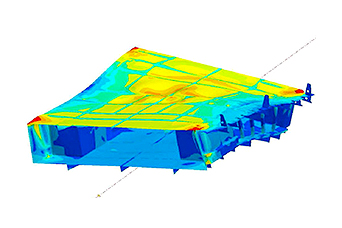

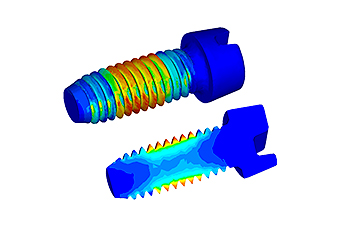

During the product development part, a virtual model is formed through pc and analysis of various conditions are executed.

By verifying the performance before producing a sample enables to design and produce the optimized product reducing the development time contributing to reduce the development cost.

For the consistent verification of the performance and endurance reliability of our product, not just the stable quality is secured but also abundant technical skill and research performance is secured through various product development.