Definition of Smart Factory

ICT integrates all production processes from product design to sales.

Advanced intelligence plants that produce custom-made products at minimal cost and time

Introduction Background

We will diversify and specialize our business with innovations for survival.

Innovation is needed to prepare for the future in accordance with the information technology era approaching the 4th Industrial Revolution.

In line with this, we can quickly respond to next-generation businesses and innovate our information system infrastructure.

Smart factories were introduced to achieve their goals.

Introduction Effect

-

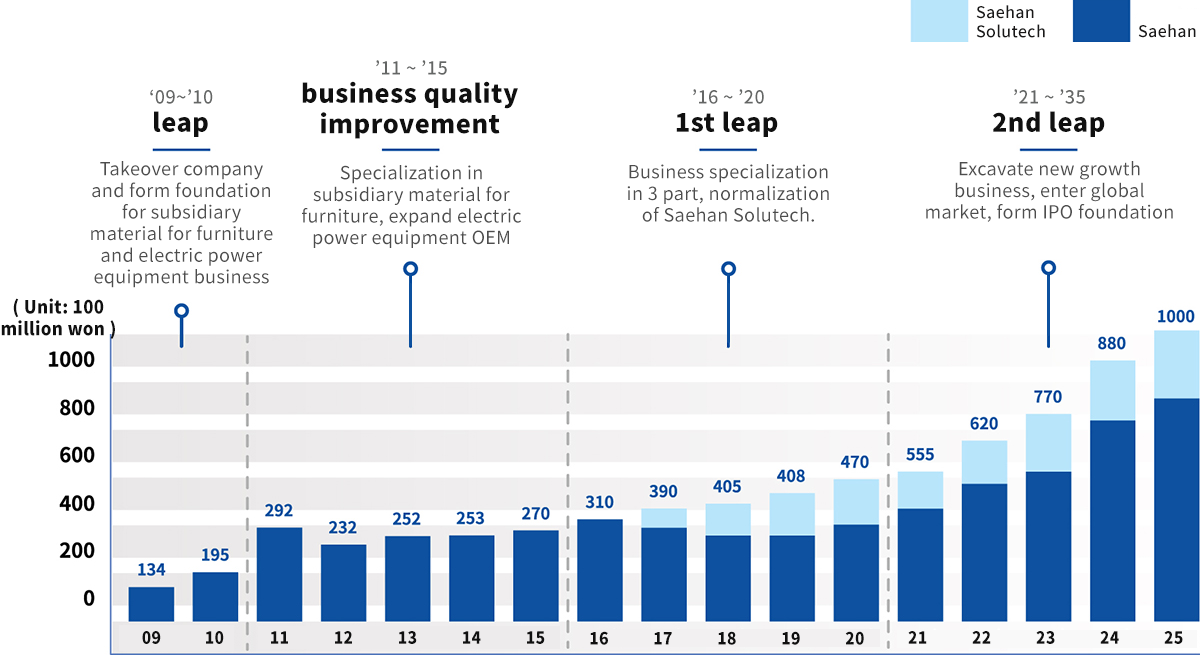

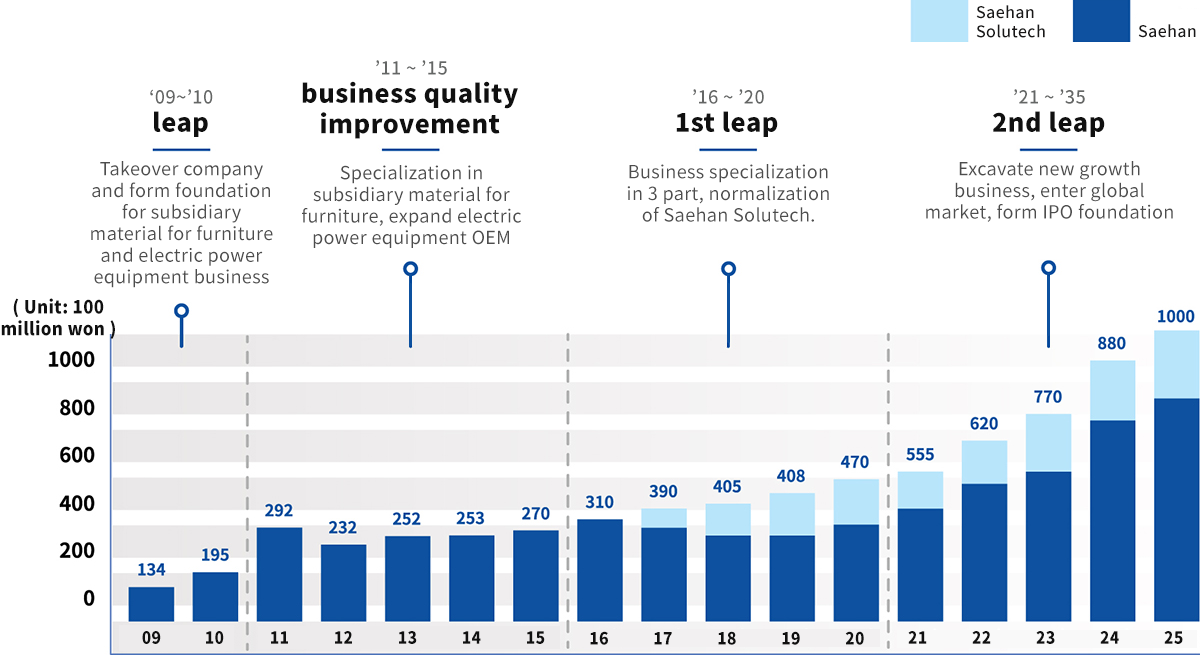

VISION 2510 : Aim 100 billion until 2025

-

⑵ Business Management

Before introducing the smart factory, the process automation technology were only formed by each process making it difficult to manage the entire process.

However after the introduction all facility or device where connected through wireless communication being able to connect data of before / after processes freely accomplishing the optimized production environment through this.

Besides management, the cost efficient is high enabling to be independent from expensive labor power and through efficient management of the stock several hundred million were reduced.

Promotion Direction & Goal

Standard Direction of Advancement Promotion

-

Establish Small-mid Size Company Type Smart Factory

- Promotion Purpose

-

Establish customized smart factor to the features of each business division

People(technology)-oriented process / Classified operation of smartification process

- Establish CPS concept intelligent production system

- 01 Customized Smart Factory

-

Establish smart factory dualization

Mass amount, simple process : Realize perfect smart factory

Small amount, multi-variety process : Establish technology-oriented management concentrated system

- Plating, packaging – Introduce automation process (reduction of manpower)

- Distribution – Management smartification

- 02 Establish Intelligent Production System

- Design CPS(Cyber Physical System) concept process

- Improve current issues through big data analysis

- Cooperation system between machine and human – Automation and introduce robot

-

Establish system for prevent / Preserve / Predict Using AI and IoT

- Promotion Purpose

- Establish facility preservation and quality prevention system using AI and IoT

- Develop business prediction model using big data analysis, deep learning, AI etc.

- 01 Facility Preservation and Quality Prevention

- Establish facility preservation system using Iot

- Detect defect through Iot and establish restriction / control system using AI

- Establish automatic connection system from obtaining order ~ delivery controlled by AI

- 02 Establish Intelligent Production System

- Develop market prediction model through big data analysis

- Predict diverse market change using AI

-

Develop Business Model Using Platform

- Promotion Purpose

- Establish business platform for individual furniture division

- Search measures using other platform

- 01 Establish Business Platform

- Search furniture division market platform

- Develop various business model connecting on / offline

- Form exclusive manpower and organization

- 02 Use Other Platform

- Business connection using other platform – Technology, design, delivery etc

- Establish distribution base – Use regional platform

Smart Factory Step-by Advancement Goal

-

Smart Step1

ERP Integrated System + Part MES

- Establish ERP system for all company

- Introduce MES production system for part of the process

- Introduce part fool proof system

- Share real-time information and provide decision making data

-

Smart Step2

Establish MES system for all process

- Establish MES production system for all process

- Production management, quality, manpower operation, facility efficiency etc.

Establish bundle monitoring system

- Link stock POP(barcode) management system

- MES+ERP

-

Extended Step3

Smart factory advancement

- Quality prediction model using AI, big data analysis, deep learning etc.

- Secure digital business model using cloud platform

- Establish production line according to the intelligent motion production system based on CPS design

- Establish strategy decision making system through introducing innovative management system

Share and integrate real-time management information through introducing step-by-step system